漫反射光电传感器英文

- 时间:2025-07-15 09:02:33

- 点击:0

Diffuse Reflective Photoelectric Sensor: The Automation Workhorse You Need ???

Imagine a robotic arm smoothly placing items on a conveyor, a smart bin opening hands-free as you approach, or a production line flawlessly counting thousands of products per hour. What invisible guardian ensures these tasks happen reliably, without physical contact? Often, it’s the diffuse reflective photoelectric sensor, a cornerstone of modern sensing technology. But what makes it so widely indispensable across industries? Let’s delve into the world of this essential automation component.

1. Decoding the Technology: How It “Sees” the World

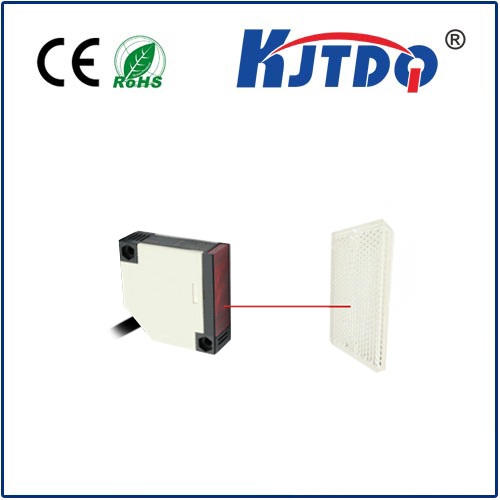

At its heart, a diffuse reflective sensor functions on a beautifully simple yet effective principle. It combines an emitter (usually an infrared LED) and a receiver (phototransistor or photodiode) within a single housing. Here’s the magic:

- The Emitter Sends: An infrared (IR) light beam is continuously projected outwards.

- The Target Reflects: When this beam strikes an object within its sensing range, the object’s surface diffusely reflects the light. Crucially, this reflection occurs in many directions.

- The Receiver Detects: A small portion of this scattered light bounces back towards the sensor’s receiver unit.

- Signal Triggered: Upon detecting the reflected light intensity exceeding a predefined threshold, the sensor’s internal circuitry triggers an output signal – typically a solid-state switch (ON when object present, OFF when absent).

The defining characteristic here is diffuse reflection. Unlike retro-reflective sensors needing a reflector or thru-beam sensors requiring a separate receiver opposite the emitter, the diffuse type relies solely on light bouncing off the target object itself. This makes target color, texture, and surface finish critical factors in its performance.

2. Where It Shines: Ubiquitous Applications

The simplicity, reliability, and non-contact nature of diffuse sensors make them the go-to choice for countless tasks:

- Object Presence/Absence Detection: The fundamental application. Is the bottle on the line? Is the part in the fixture? Is a product present in the packaging? ?

- Position Verification: Ensuring components are correctly seated before the next process step (e.g., in assembly or machining).

- Counting: Accurately tallying products, packages, or items passing a point on a conveyor belt. Widely used in logistics and high-speed sorting systems.

- Level Detection: Monitoring fill levels in bins, hoppers, or boxes (detecting the presence/absence of material at a specific height).

- Small Part Detection: Ideal for sensing tiny components where other sensor types struggle.

- End-of-Travel Detection: Verifying a mechanism (like a door or actuator) has reached its intended position.

- Hands-Free Control: Found in smart sanitary equipment (automatic faucets, soap dispensers, flush mechanisms), automatic doors, and gesture-based interfaces.

3. Strengths and Limitations: The Balanced View

Understanding both sides is key to optimal application:

?? Pros:

- Simple Installation: Only one unit to mount and wire. No alignment needed with a separate reflector or receiver unit across the path.

- Cost-Effective: Generally the most economical photoelectric sensor type.

- Compact Size: Single housing design fits easily into tight spaces.

- Versatile Object Detection: Works effectively on a wide range of non-reflective targets.

- Non-Contact Sensing: Eliminates wear and tear on both the sensor and the target.

?? Cons:

- Limited Sensing Range: Typically offers the shortest range among the three main photoelectric types (diffuse, retro-reflective, thru-beam) due to reliance on weak diffuse reflections. Ranges can vary significantly (often a few cm to a meter or two) depending on the target`s reflectivity.

- Target Dependency: Performance is heavily influenced by the target`s surface properties. Highly reflective or very dark/absorbent targets, or targets similar in color to the background, can cause unreliable detection or require careful threshold adjustment. Background suppression technology (BGS) helps mitigate this for specific applications.

- Sensitivity to Environment: Can be affected by ambient light (sunlight, bright lamps), dust, fog, or steam interfering with the light path. Models with modulated light (pulsed IR) and suitable housings (IP ratings) help combat this.

- Background Interference: Objects behind the intended target might cause false triggers if they are closer and more reflective unless using a background suppression variant.

4. Choosing the Right Sensor: Key Considerations

Selecting the optimal diffuse sensor requires evaluating several factors:

- Target Properties: Material, color, surface finish (matte vs. glossy), size, and shape. Test with actual samples if possible!

- Required Sensing Range: How far away does the sensor need to reliably detect the object? Always choose a sensor with a published operating range exceeding your maximum required distance, factoring in target reflectivity.

- Environmental Conditions: Exposure to dust, moisture, chemicals, vibration, or extreme temperatures? Select an appropriate IP rating (Ingress Protection) housing (e.g., IP67 for washdown environments common in food & beverage processing).

- Output Type Needed: Discrete switching output (PNP/NPN transistor)? Analog output for distance measurement? Relay output?

- Response Time & Switching Frequency: How quickly must it detect objects? Critical for high-speed applications.

- Connectivity: Standard cables, quick-disconnect (M8/M12 connectors), or IO-Link for smart diagnostics?

- Special Features: Need adjustable sensitivity? Background suppression (BGS) for ignoring more distant objects? Foreground Suppression (FGS) for very close targets? Precise optical filters can enhance performance against ambient light interference.

5. Enhancing Performance: Background Suppression (BGS)

For applications where the target might be in front of varying backgrounds or where distance matters, Background Suppression (BGS) diffuse sensors are revolutionary. They utilize triangulation principles:

- The emitted light hits the target.

- The reflected light is focused onto a position-sensitive receiver element (like a CCD array) within the sensor.

- The sensor analyzes the angle (position) of the reflected light spot.

- Light reflected from an object within the defined sensing range hits at one position, triggering the output.

- Light reflected from an object beyond the set sensing range (or the background) hits at a different position and is ignored.

This BGS technology dramatically improves reliability when targets need to be detected reliably regardless of color against potentially interfering backgrounds, making it ideal for applications like conveyor lines or object presence on